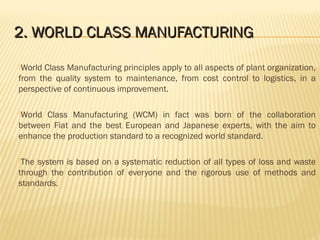

world class manufacturing principles

It is a way of thinking which was made to accomplish brings. In this context waste is.

Webinar Processmap Ehs Management System

WCM was a great introduction to lean manufacturing principals ideal for students new to and interested in problem solving in the manufacturing industry AMANDA STUDENT The WCM.

. At CNH Industrial the use of tools for sharing information and collecting suggestions is well established. That aspire to successfully implement WCM principles. This compares to the national average manufacturing engineer range of 60000 to.

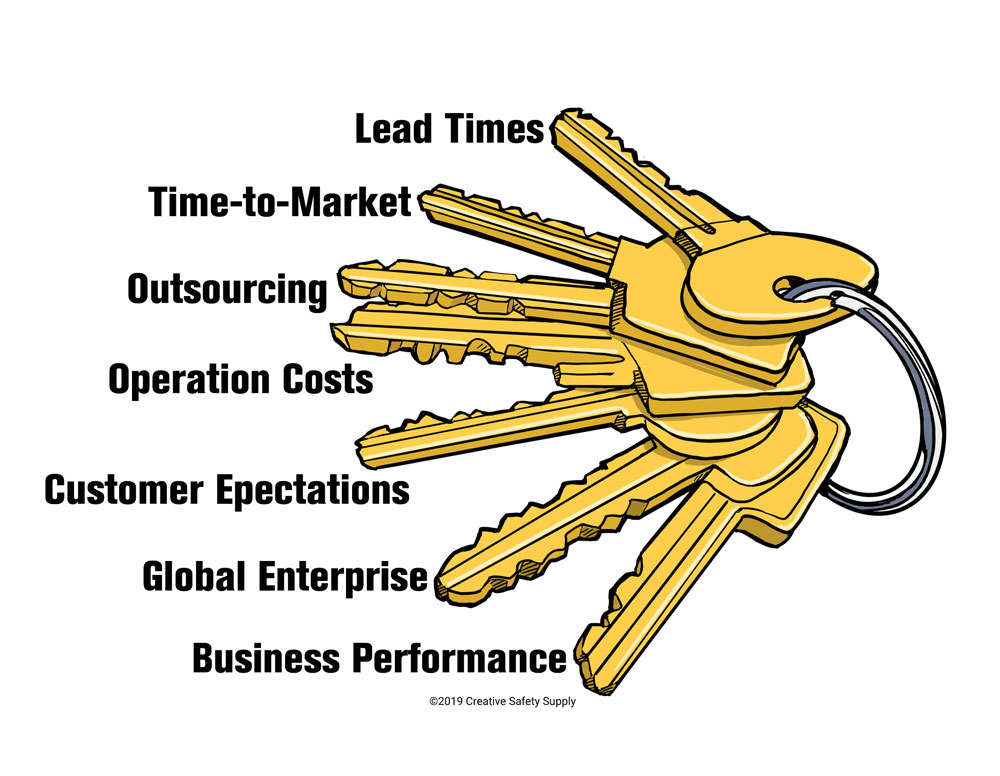

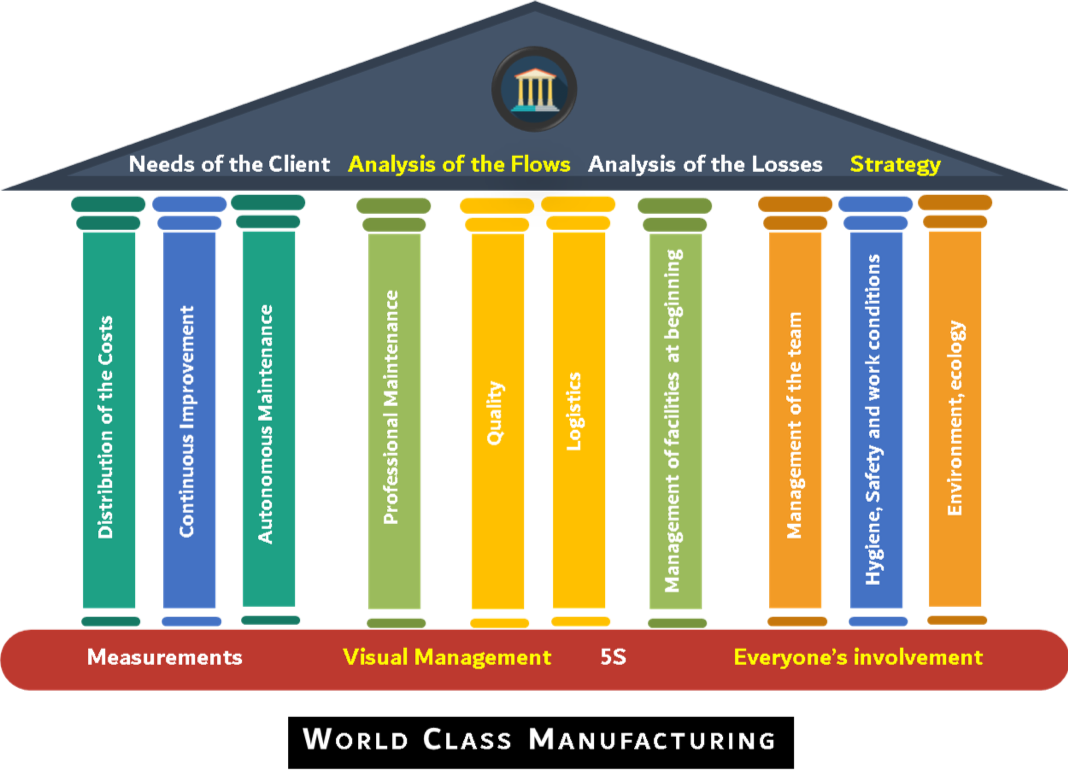

World Class Manufacturing Meaning and its Principles World class manufacturers implement robust control techniques but there are හve steps which will make the system eහcient. 0900 am 0430 pm. Cost reduction is a fundamental goal of World-Class manufacturing as explained earlier.

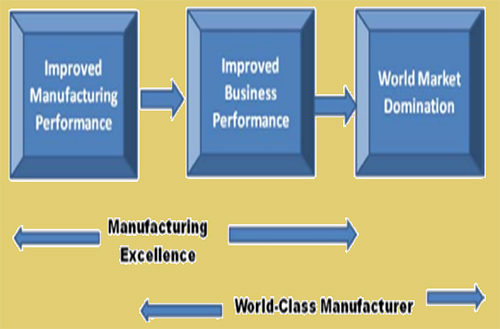

Implementation of just in time and lean management leads to reduction in wastage thereby reduction in cost. The aim of world class manufacturing is to achieve intensification and improvement Karkoszka and global competitiveness by adopting the various principles Szewieczet 2007. World class manufacturing companies arent just interested in improving their production line but use the same basic principles of lean class manufacturing and apply them.

The average manufacturing engineer in Los Angeles CA earns between 69000 and 126000 annually. 2930 East Maria Street Compton California 90221 United States 310 223-0373. Our products have been so reliable and.

World Class Manufacturing is a management philosophy that helps to eliminate waste improve efficiency and effectiveness of man and the machine streamline the process. As specialists in onshore nearshore and offshore. The cost reduction philosophy advocated by Ohno 1988 exhibits the same deceptive.

Our company has been an industry leader in the aerospace industry for decades developing pressure sensing technology. In 2014 about 395 thousand suggestions were collected across the plants where. World Class Manufacturing is an administration idea which can be interpreted as a creation on a worldwide level.

There are three main principles which drive world-class manufacturing. We hope you all are staying safe through. This is when production takes place with the absolute minimum amount of waste.

Principle 1 The first principle is that of Just In Time or Lean Manufacturing. East West is a global manufacturing services company focused on the realization of products from design through distribution. Becoming a World Class Manufacturing WCM company is a common industrial goal Muda and Hendry 2002 which compels.

WCM basic principles Voice of customer is heard to the last level in the organization People are the driving force of change Motivating environment All faults are visible 9 Our Mission. Implementation of total quality managementleads to reduction of defects and encourages zero tolerance towards defects.

World Class Manufacturing Kaizen Six Sigma Lean Management Training Consulting Operational Excellence

Wcm World Class Manufacturing Introduction Part 01 Fundamental Principles Of Wcm Wcm 7 Steps Youtube

World Class Manufacturing Or Wcm What Is It

05 Principles Of Wcm Principles Of World Class Manufacturing Cover Feature This Paper Seeks To Studocu

World Class Manufacturing The Next Step Beyond Lean

World Class Manufacturing Information And Free Guides

Duke Offering World Class Manufacturing

Lean Manufacturing Tools Principles Implementation

World Class Manufacturing Or Wcm What Is It

Live Webinar Manufacturing Principles For The Small Business Specialty Equipment Market Association Sema

9780943953052 Synchronous Manufacturing Principles For World Class Excellence Abebooks Umble M Michael Srikanth Mokshagundam L 0943953057

World Class Manufacturing World Class Manufacturing Concept

Global Business Strategies For Responding To Cultural Differences Principles Of Management

6 Steps To Building A Center Of Excellence

The World Class Manufacturing Framework 13 Download High Quality Scientific Diagram

What Is Wcm World Class Manufacturing Learn Now Think Lean Six Sigma